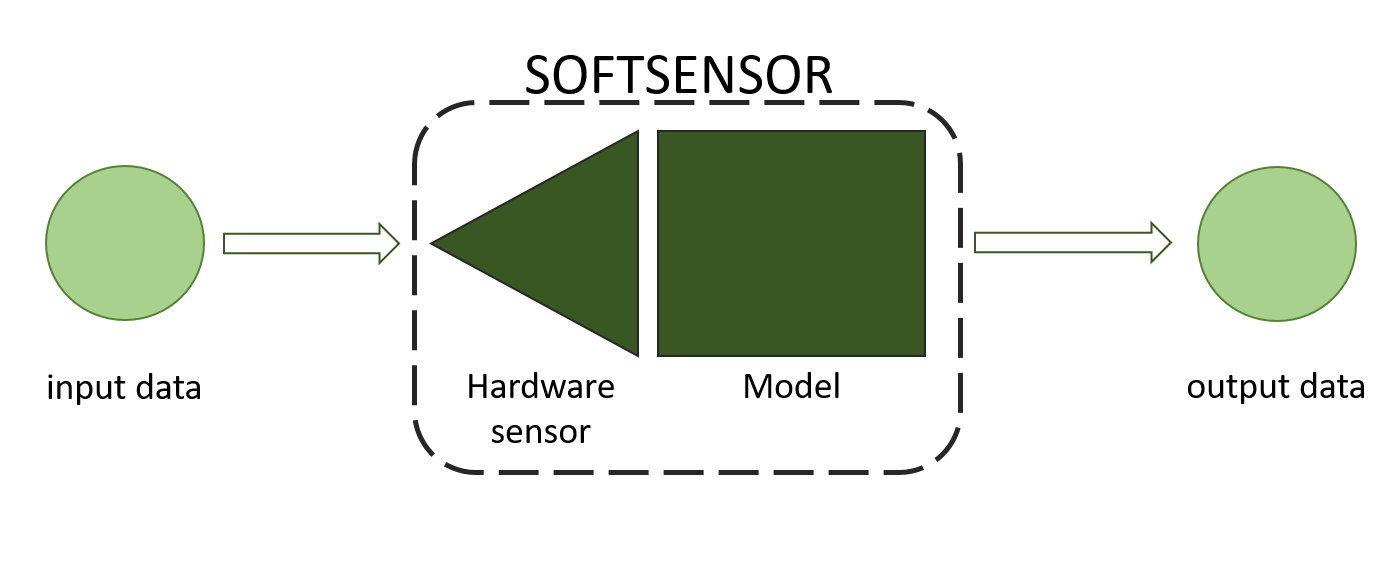

A software sensor is a combination of process data (sensor input), measured by hardware sensors, and a model that analyzes these input data in order to obtain new process information (sensor output). Hence, a software sensor implies an indirect measurement of the desired variable.

The development of software sensors can be carried out using three different types of methodologies: Model driven estimators (e.g. Luenberger observers, adaptive observers, interval observers, Kalman-Bucy filters), data-driven estimators (e.g. Artifical Neural Networks and chemometrics), and hybrid models (a combination of the beforehand mentioned estimators).

Review Paper: Porras Reyes, L., Havlik, I. & Beutel, S. 2024. Software sensors in the monitoring of microalgae cultivations. Rev Environ Sci Biotechnol. https://doi.org/10.1007/s11157-023-09679-8

Our consortium research interests are focused mainly in the use of several microalgae strains including the well-known Chlorella sp., Nannochloropsis sp., Haematococcus pluvialis, Tetraselmis sp., and Spirulina sp. Other microalgae strains of our interest are Tisochrysis lutea, Cylindrotheca closterium, Picochlorum sp., Scenedesmus sp., Tisochrysis lutea, Chaetoceros muelleri, Thalassiosira weissflogii, Thalassiosira pseudonana, Diacronema lutheri, and Rhodomonas salina.

Our current on-line monitoring methods for microalgae cultivations include traditional physicochemical parameters (pH, temperature, oxygen production rate, light energy supply, nutrients concentration). However, other measuring devices available in our consortium include optical coherence tomography (OCT), confocal laser scanning microscopy (CLSM), Fourier-transform infrared spectroscopy (FTIR), fluorescence spectroscopy, near infrared (NIR) and UV-VIS spectroscopy. This set of devices provides relevant data for the development of software sensors.

For our research interests, the most relevant process parameters in microalgae culture include biomass estimation (e.g. dry cell weight, cell concentration), cell viability, pigment concentration (e.g. astaxanthin), lipid concentration, nutrient status (e.g. NO3, PO4), real time productivity, physiological state of cells, recognition of microalgae-bacteria consortium or different types of microalgaes. The estimation of some of these parameters will be performed by using software sensors such as chemometrics, observers (e.g. interval observers and high gain observers), and artificial neural networks.

Institute of Technical Chemistry

Leibniz University Hanover

Callinstraße 3-9

30167 Hanover

Read the privacy policy of this site.